Multi-stage Evaporation

Lot of water needs to be evaporated in the large-scale industry production, so it is required abundant energy to heat the water to produce steam. Multi-stage evaporation is aim to reduce its consumption of heating steam during this process.

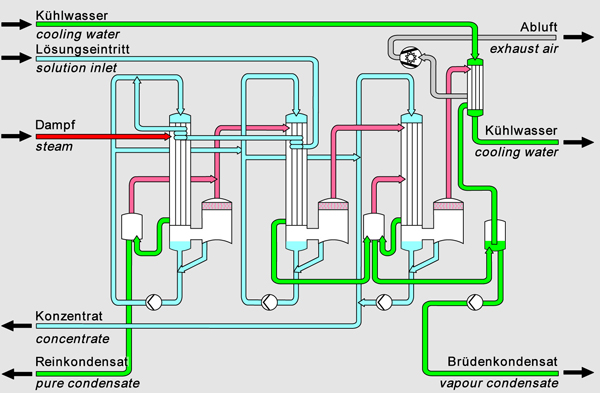

After heating steam entered into an evaporator, the solution is heated and boiled. The generated secondaryary steam can be utilized because its pressure and temperature are lower than the heating steam (Live steam). During the multi-stage evaporation, this secondary steam will be used as heating steam to bring into another evaporator only if the pressure and the boiling point of solution in its chamber is lower than the previous evaporator. Similarly the secondary steam from this secondary evaporator will be used as heating steam for the third evaporator. In this way, each evaporator can be called ¡°One stage¡±, and several evaporators will be connected and operated together as multi-stage evaporation system. The evaporator added by live steam is the first stage, and the secondary stage is the one which uses the secondary steam from the first evaporator.

This system achieves the circular application of the heating energy and reduces its consumption so as to reduce the cost and increase the efficiency. .

With the technical support of Ebner GmbH & CO. KG, we designed and manufactured dozens of 14-stage evaporation systems for domestic and foreign enterprises and received the favorable comments for the good economic benefits.